Product Categories

Contact Us

24-hour service hotline:

Address:No. 29, Wanggang Xinnong Road, Nangang District, Harbin

Email:hg@hrbtool.com

Website:http://www.hrbtool.com

Product Center

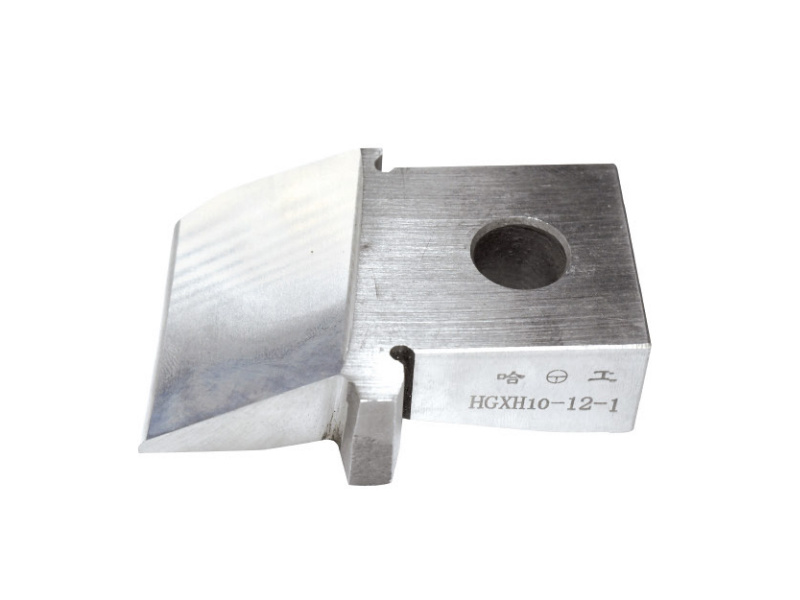

Used for the fine cutting of large gears in arc-toothed bevel gears, the radial and axial dimensions of the cutter teeth do not increase, while the shims in the milling cutter disc do increase. After assembly, the milling cutter produces a radial increase. Any increase error caused by the combination can be adjusted by the fine-tuning screw. The same disc milling cutter can adjust different cutter offsets within a certain range by changing the increase shims.

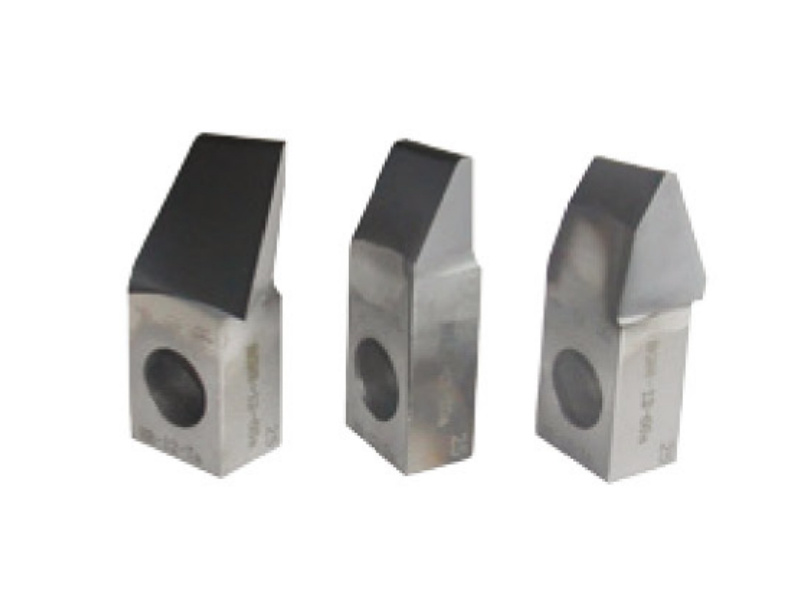

Used for spiral forming fine cutting of large helical gears with arc-shaped teeth, the milling cutter has radial and axial tooth increments, and the machining process involves axial movement spiral hobbing.

Rough machining of large gears for arc-toothed bevel gears and quasi-hyperbolic gears

Rough machining of large gears for arc-toothed bevel gears and quasi-hyperbolic gears

Used for precision cutting of large and small gears of arc-toothed bevel gears and quasi-hyperbolic gears, with a maximum available cutter and blade diameter of 60"

Used for fine cutting of the convex surface of small wheels of arc-toothed bevel gears and quasi-hyperbolic gears, it can provide a maximum cutter and blade with a nominal diameter of 60"

Used for fine cutting of the concave surface of small wheels of arc-toothed bevel gears and quasi-hyperbolic gears, it can provide a maximum cutter and blade with a nominal diameter of 60"

Used for machining small module arc-toothed bevel gears and quasi-hyperbolic gears

Oerlikon milling cutter bar (i.e., Klingelnberg & Gleason milling cutter)

Oerlikon milling cutter bar (i.e., Klingelnberg & Gleason milling cutter)

Used for machining small module arc-toothed bevel gears and quasi-hyperbolic gears

![[ Follow us ] [ Follow us ]](https://omo-oss-image.thefastimg.com/portal-saas/pg2025060915471625832/cms/image/c7d8e882-48f5-47ab-b034-5cf0d8cae96b.png)